laboratory instruments distributor

Laboratory mixer - mechanical stirrer >> Over head mixer

What is a laboratory mixer or mechanical stirrer?

Laboratory mixer is a set of different systems for intense stirring and mixing of different samples. In this way, using a laboratory mixer, you will get the right mixture for your applications.

Although there are many laboratory mixers on the market, magnetic stirrers are the most common. In this guide, you will learn more about different types of stirrers.

Stirrers may have strong magnets that allow the magnetic strip inside the tube to stir the liquid. Stirring speed also varies depending on your mixer. Other than that, most of them have microprocessors with rotary buttons.

Rotary buttons allow quick, accurate and easy adjustment while maintaining a constant temperature and speed. In this guide, you will become more familiar with the parts and components of laboratory mixers.

Now let’s look at some of the benefits of a laboratory mixer.

Laboratory mixer parts and components

The laboratory mixer depends on different parts to assist in the mixing process. In this section, you are going to learn about some of the key components of a laboratory mixer.

First. The impeller is the rotating part of the laboratory mixer to help move the material.

Second. Canister Wall lets you inject liquids into a blender.

Third. The shovel is a blender that allows you to mix, blend and shape ingredients properly.

iv. A knife for shredding dispersing and mixing blades to disperse and reduce particle size.

v. Stansing Pansis Place the container in which you want to mix the ingredients.

vi. A printer that prints all parameters while working.

vii. PLC program controller that controls and records all data during the mixing process. It also controls the speed of the shredder blades and the shaking of the paddle. Apart from that, it meets the technical requirements of granulation.

viiii. Rubber wheels that can rotate 360 degrees allow you to move and maneuver the mixing machine.

ix. Video shows you the progress of the mixing process

X. Intrinsically Safe (IS)

xi The motor unit that drives the moving parts of the laboratory mixer. This allows the car parts to move freely.

xii. The electric stand and electric landing is part of a laboratory mixer that you can adjust to the height you need. It is an automatic base that draws its power from an electrical source.

xiii. The bench stand is the main base for the entire laboratory mixer. This gives the laboratory mixer good stability for normal operations.

After a thorough understanding of the components, let’s examine the working principles of a laboratory mixer.

Laboratory Stirrer Features

The tray has an adjustable height with a step of 300 mm

Adjustable at different speeds by speed control

Ability to use a variety of licenses for better coordination with the type of user

Ergonomically designed for the user

The mechanical mixer is divided into several main parts that make it easy to troubleshoot and repair.

The material of this tank is stainless steel in the parts that are in direct contact with the material and in other parts it is covered with electrostatic polyester paint.

Maximum operating temperature: 40 ° C

Maximum operating humidity: 90%

Advantages of laboratory mixer

In any laboratory, it is important to have equipment that assists you in specific functions. Another key benefit is that it saves you a lot of time.

In this section, we are going to look at some of the key benefits of using a laboratory mixer

Some of the benefits are:

· High cleaning standards

Hygiene and cleanliness are the most important factors in any laboratory.

For this reason, it is important to use a laboratory air mixer to maintain high standards of cleanliness.

· Mix thoroughly

Before moving to the next stage of production.

Most ingredients must go through a thorough mixing process.

Using a laboratory mixer helps with a homogeneous mixture.

· Improving Performance

Using a laboratory mixer improves and simplifies the efficiency of your operation.

Time is of the essence, and the more time you save, the more money you will save and maximize your profits.

·Maximum flexibility

The flexibility of the device allows you to develop different types of products.

These products can include emulsions, suspensions, lysoles and granular products.

· Increase direct scale

Simplicity in scaling also shows the ease of operation.

Representative results

You are sure to get dramatic results from a variety of mixtures.

This includes the results of the smallest number of products.

Safety

The use of a laboratory mixer ensures the safety of the user from dangerous and corrosive elements.

Also make sure there is no contamination

With that in mind, let’s move on to the different types of laboratory mixer systems.

Types of laboratory mixer systems

Due to the complexity of the mix, you will see different types of laboratory mixers. Certain types of solutions require certain types of laboratory mixers.

In this section, we review some of the existing laboratory mixer systems.

1. High cutting laboratory mixer machine

High-cutting laboratory mixer machine transfers or distributes different stages of materials to a continuous stage.

This process focuses on mixing materials that are usually unmixed.

This machine uses different parts such as rotor, stator to get a uniform mixture.

You can use it to make suspensions, emulsions, granular products and lysoles.

It is a common equipment in the chemical, adhesive, food, cosmetic, plastic and pharmaceutical industries.

2. Multifunctional laboratory mixer

You can use a multi-purpose laboratory mixture to perform the following activities:

mix

The multi-purpose laboratory mixer helps to combine different materials.

The end result will be a uniform mixture.

· Homogenization

You can use this device to combine different elements to create a uniform mixture.

This helps to make a uniform solution of two liquids or insoluble elements.

· Dissolving

You will use the device to combine a solid to form a homogeneous mixture in a liquid.

In the end, you will be able to find a consistent solution.

· Disjoint

This device can also help you break different elements into very small units.

The elements lose their power and cohesion and gradually fall into smaller parts.

Emulsifier

You can use the machine to mix different types of unmixable liquids to create emulsions.

This device helps emulsify liquids of different thicknesses.

3. Laboratory Vortex Mixer

You can also call it a vortexer.

This device is very simple that you can use to mix small vials of liquids in the laboratory.

You can use it for the following:

First suspend cells in a microbiology laboratory or cell culture

Second, a mixture of assay reagents in analytical or biochemical laboratories

It has an electric motor and a drive shaft with a vertical direction.

4. Laboratory mixer (magnetic stirrer)

You can also call it a hot plate.

Uses a magnetic field to rotate the stirrer rod to create a uniform mixture.

You can use it in a hermetic container with a complete seal without the use of complicated torsion seals.

Magnetic stirrers are a common machine because they are more efficient and extinguishing. Do not move the outer part to prevent damage to other parts of the device.

5. Laboratory ribbon mixer

Laboratory ribbon mixers or mixers have horizontal U-tanks with a special ribbon mixer. The ribbon stirrer has an outer and inner spiral stirrer. As the inner bar moves the material in one direction, the outer bar moves it in the opposite direction.

The strips move at a certain speed, which ensures a complete and uniform composition.

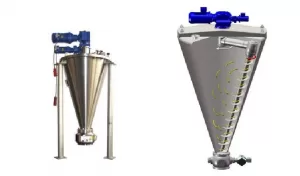

6. Laboratory cone mixer

You can use this type of mixer to combine different elements such as good chemicals and medicines.

Remember, you can practically use it to homogenize solids and bulk powders that are sensitive in nature. This is a gentle mixer with minimal power consumption.

In this section, you will get acquainted with different types of laboratory mixer designs with their advantages and disadvantages.

Power Sticks and Ring Drive Head Stirrers

It is a type of laboratory mixer with electric drive head and stainless steel material. It also has a dispersion blade to reduce particle size and material dispersion. It weighs little and you can easily move it from one place to another. However, it limits you to certain mixing programs.

Air Strand & Ring Drive Head Stirrers

Laboratory mixer design has an air driver head that works with a mixing head. It also has a ring drive head that helps move the stirrers.

This device is portable and has a rod base to support the drive mixers. The air rod does not provide enough power for other powerful applications.

· Head and ring drive heads / standard packages

This package has a hard drive head with stainless steel shaft. The drive head is lightweight and enables proper mixer operation. You do not need a power supply to work with this device.

Mixer lift

This allows you to use up to 5 gallon containers for your mixing programs. This is especially true in the food industry, especially for mixing dough.

This saves time when you may use manual mixing of the mixture.

It is also small and portable, which allows you to work it on the bench.

Roller mill

Includes a gallon and two quart cans for milling and mixing small batches of paint, glue and ink

This machine uses grinding like metal balls to crush particles 100 times its desired particle size.

This device has an overload protection unit and its maximum capacity is up to 12 pounds.

It also has a continuous 1/75 HP fan cooling motor.

Shaker

These are a gallon gyroscopic shaker for use with a variety of materials. It depends on the electricity supply. It also has a gearbox and you can use one with the lowest or highest noise level.

The gears do not need to have pulleys, shift belts and friction actuators. This device has a timer with a one-step closing system.

Gear and air mixer drive closed

It includes an air actuator head, a stainless steel shaft and a blade impeller.

The drive head has a light weight and variable speed for mixing different solvents and flammable materials.

Therefore, in case of any defect, it reduces the risk of flame.

It has a rod and a ring that allow you to mount the drive head on a nut with a C-pin.

The air motor also provides the flexibility of the device.

Not suitable for use with electricity as it may cause a flare.

Air mixer with chuck

Because it is air-driven, it poses a lower risk of creating a flame instead of electric mixers. It has a rod and a ring bracket for mounting the drive heads.

When you use it with enough energy, it creates maximum stimulation. The air motor helps to improve the reliability and flexibility of the mixture.

Despite the different designs, laboratory mixers have different parts that complete it.

Performance of laboratory mixer and stirrer

Let’s take a step-by-step look at how the mixer works.

First of all, you must first turn on the device.

Then, before setting the device from the control panel, you can measure and place the necessary materials.

Step one:

Rotor blades that move or rotate at very high speeds apply very powerful suction.

Suction pulls liquids and solids from the bottom of the container upwards.

The mixture of liquids and solids moves to the center of the work.

second stage :

The centrifugal force directs the material to the working edge of the machine.

The machine grinds the material between the end of the rotor blade and the inner wall of the stator.

third level :

Intense hydraulic cutting is followed by high-speed material movement.

The material moves through the holes inside the stator.

After that, the materials circulate in the main body of the mixture.

Step 4:

At this stage, the material moves radially from the head to the mixing vessels at a very high speed.

As this process continues, your supply of fresh ingredients will continue.

This allows the work to absorb more material to maintain the mixing cycle.

Horizontal radial suction and discharge creates a circulating pattern that minimizes aeration.

Aeration is often the result of a disturbance in the fluid level.

From the edge of the mixer, you can now collect the mixture and continue the other steps.

Things to consider when buying a mixer for the lab

The availability of many manufacturers gives you the freedom to choose from a variety of mixers. However, there are some machines that are not reliable.

Here are some things to look for when selecting a lab mixer.

- Brand and model

- Laboratory mixing technology

Capacity - Efficiency

- Quality observance – CGMP, CE, EN standards, etc.

- · Materials

- Target

- Mixing speed

- Additional capabilities

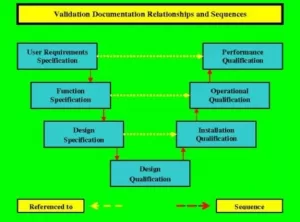

User requirements for laboratory mixers

In this section, you will learn the specifications that you should know or have before working with a laboratory mixer.

Provides user required specifications:

First. Installation competence for installation steps

The second is performance competence for equipment performance

Third, product or performance competence for equipment performance

In many cases, you have to provide the required user information.

This allows you to have the luxury of equipment that you can use properly.

Therefore, the manufacturer offers a specific design of equipment that matches your specifications.

Some of the factors that you can customize in the user profile are:

First. Intended use

Second is the capacity and availability of space

Third, the requirements for cleanliness and accuracy of the tool

iv Specific equipment requirements.

In addition, you can also purchase equipment and get acquainted with the user’s needs.

Most manufacturers usually have the equipment manual.

This manual will guide you through the specific needs of the device user.

Let’s look at some of the main uses of laboratory mixers.

Applications of laboratory mixer

You can use a laboratory mixer in several cases. You should note that the program determines the type of device you intend to use.

Here are some programs that require a laboratory mixer:

Detergent industry

To prepare detergents, you have to mix a number of different types of ingredients.

You can achieve this by performing laboratory tests using a laboratory mixer.

After that, you can proceed with the same formulas and produce detergents on a large scale.

Pharmaceutical industry

Pharmacy is also formed as a result of mixing different types of substances.

The combination of these substances creates drugs that treat certain diseases.

With the help of a laboratory mixer, you can mix these ingredients thoroughly to achieve a uniform drug solution.

Construction materials manufacturing industry

Building materials such as cement need thorough mixing to achieve a good concentrate.

The ingredients of the mixture must be completely perfect to form a permanent, concrete solution.

The laboratory mixer helps build a sample that you can replicate for large-scale production.

Mining industry

In the mining industry, there is a need to use a laboratory mixer.

You can use special mixers such as two-shaft laboratory mixers.

This is a special machine that allows you to mix minerals in the mining industry.

Food processing industry

No matter how sensitive it is, you should have a laboratory mixer that can help you prepare a good nutrient solution.

You can find a laboratory mixer used in the juicer industry, where the mixer mixes different fruits.

Apart from that, you can use it to get the perfect meal mix.

Chemical industry

Chemicals are very sensitive and you need a mixer to mix different solutions.

The mixer protects you from chemical corrosion and makes it safe to use.

To achieve a uniform mixture of chemicals, you must use certain types of mixers.

Cosmetics industry

To achieve a uniform mixture of cosmetics, you must use a laboratory mixer.

The cosmetics industry relies on a laboratory blender to mix samples of its ingredients.

Successful integration of samples in the manufacture of cosmetics leads to mass production of products.

The best supplier of laboratory mixer

Daneshvar Shimi Company is an importer of laboratory equipment, laboratory and research equipment and chemicals. Daneshvar Shimi Company also has the ability to supply spare parts for laboratory equipment and laboratory devices purchased by centers that have problems.

Products related to milk and dairy laboratory >>

Somatic cell counter device

Application: Milk and Dairy Laboratory

Somatic counter counter device for counting milk somatic cells

Caldeal system of digestion and distillation

Application: Milk and Dairy Laboratory

Caldeal system for digestion and distillation to measure protein

Soxhlet device

Application: Milk and Dairy Laboratory

Soxhlet device for measuring fat

Automatic raw fiber machine

Application: Milk and Dairy Laboratory

Raw fiber device for measuring fiber, ADF and NDF

Milk scan machine

Application: Milk Fraud Laboratory

Milk autoanalyzer to detect milk fraud by FTIR method

Valve centrifuge

Application: Milk and Dairy Laboratory

Milk centrifuge to separate fat from milk

Chryscope device

Application: Milk and Dairy Laboratory

Chryscope device for measuring water added to milk

Butterometer milk, cheese and cream

Application: Milk and Dairy Laboratory

Milk butyrometers for milk, cheese, cream and butter

Incubator device

Application: Milk Fraud Laboratory

Incubator for cell and microbial culture

Laboratory chemical hood

Application: Milk and Dairy Laboratory

Chemical hood to remove chemical vapors from the laboratory

Laminar microbial hood

Application: Milk and Dairy Laboratory

Microbial hood for purification and removal of organic agents

Avon-four machine

Application: Milk and Dairy Laboratory

Oven or oven machine for drying laboratory equipment

Email : info@d-chemi.com

site : www.d-chemi.com